Welcome

to the Oct 2006 Trackwork page 2

of the FSMR website

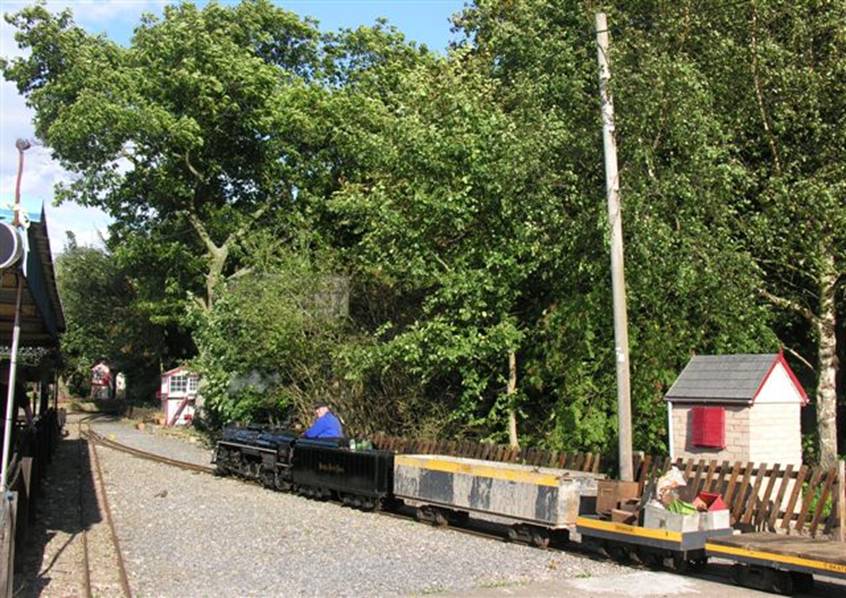

These photos were taken during the October track weekend in 2006 when 5 panels were lifted and replaced on

badgers curve in one weekend. At the same time the opportunity was used to

install a sleeper retaining wall against the earth bank at this location.

The works train in use over the weekend, having the luxury of

steam power in the diesels absence on its heavy repair and overhaul this

winter.

Two panels are already installed and ballasted. The tractor is

completing compacting the loosened bed before the geo-tex is applied. The newly sleepered

panel will then be connected onto the ballasted panel.

The laser level ( setup at the beginning)

is used to maintain the gradient profile throughout the new length

After setting the track height using the laser, the track is then

ballasted. There are two 2 ton ballast trucks on the SMR works train. One has

end discharge (as shown here) the other has side discharge doors. The two run

in pairs so that the whole section of track can be ballasted effectively.

Re-loading is carried out at the ballast tip by the station using

the tractor loader

After being loaded with stone, the

Apart from the

two 4 axle ballast trucks,

the works train usually consist of a flat truck for general conveying of

sleepers etc ( also adapted to take the petrol driven 1000 l weed-killing tank sprayer). There is also a 3

axle short wheelbase truck carrying fishplates, spikes and bolts shown ns shot.

Also out of shot is the

twin cylinder diesel 3 phase generator / welding wagon. An

essential piece of equipment on any track day.

If there is a large number

of personnel, a passenger coach is also added to the consist